hey..!

Welcome to My Personal Website!

...I'm Reza Mesgar...

In this website I am going to introduce the projects that I worked on so far

Also You can download my resume from here!

Welcome to My Personal Website!

...I'm Reza Mesgar...

In this website I am going to introduce the projects that I worked on so far

Also You can download my resume from here!

Experiences

My Skills

My Interests

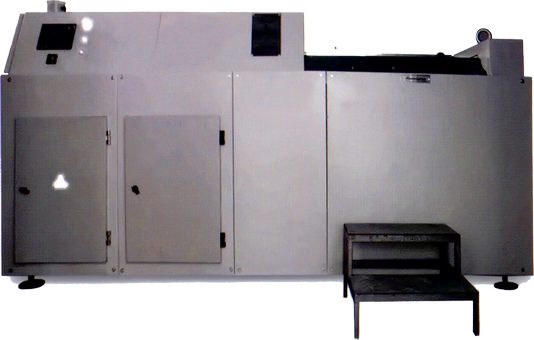

SARAY-1 & SARAY-2

SARAY sterilization systems are autoclaved based sterilization systems which designed in order to sterile both waste and hospital equipment.

SARAY-1 is a hospital waste disposal, that uses autoclave as the principle of sterilization of the wastes.

It has two sterilization cycles. Advanced and standard.

In advanced cycle the temperature is about 134 degrees.

In standard cycle the temperature is almost 121 degrees.

The most important issue in programming this device was the safety and the accuracy of the cycle.

SARAY-2 is a SARAY-1 that a shredder has been mounted on it. Programming this device has to be in a way that the electro motor and the gears of the device should be in the safe status. if the waste has got stuck in the shredder, the electromotor would turn in the reverse direction and then continue to work.

The number of turns of the gears also could be monitored by applying capacitive sensors.

SARAY sterilization systems are autoclaved based sterilization systems which designed in order to sterile both waste and hospital equipment.

SARAY-1 is a hospital waste disposal, that uses autoclave as the principle of sterilization of the wastes.

It has two sterilization cycles. Advanced and standard.

In advanced cycle the temperature is about 134 degrees.

In standard cycle the temperature is almost 121 degrees.

The most important issue in programming this device was the safety and the accuracy of the cycle.

SARAY-2 is a SARAY-1 that a shredder has been mounted on it. Programming this device has to be in a way that the electro motor and the gears of the device should be in the safe status. if the waste has got stuck in the shredder, the electromotor would turn in the reverse direction and then continue to work.

The number of turns of the gears also could be monitored by applying capacitive sensors.

Drum Separator (click for more information)

After working two years as an engineer in Kousha metal industries company, I worked as a researcher and also a designer in research and development team of the company, my first try was successful in design and building a separator of Iron ore in Iron mines. It worked perfectly by magnets and a huge metal cylinder which rotates and a brush separate the ironic parts.

my second try in making an electrical magnets for the separator was not successful because of huge amount of electrical power consumption of the magnets' driver, also there was a problem in magnetic fields of the electrical magnets and magnet coils, This project was a great experience for me.

After working two years as an engineer in Kousha metal industries company, I worked as a researcher and also a designer in research and development team of the company, my first try was successful in design and building a separator of Iron ore in Iron mines. It worked perfectly by magnets and a huge metal cylinder which rotates and a brush separate the ironic parts.

my second try in making an electrical magnets for the separator was not successful because of huge amount of electrical power consumption of the magnets' driver, also there was a problem in magnetic fields of the electrical magnets and magnet coils, This project was a great experience for me.

Edible Oil Filler

This machine is capable of filling 4 bottle of edible oil simultaneously, and the net weight of the oil can be adjusted through the HMI of the device. The measuring mechanism is based on load cells, which were mounted on 25 liter reservoirs on the top of the device.

In order to fill the bottles the oil circulated in a pipe and then if a station has been selected, the corresponding valve will be actuated and then weight’s differences of oil that is poured into bottles would be measured by load cells

It can fill bottles with 1 liter capacity to 4.5 liters.

This machine is capable of filling 4 bottle of edible oil simultaneously, and the net weight of the oil can be adjusted through the HMI of the device. The measuring mechanism is based on load cells, which were mounted on 25 liter reservoirs on the top of the device.

In order to fill the bottles the oil circulated in a pipe and then if a station has been selected, the corresponding valve will be actuated and then weight’s differences of oil that is poured into bottles would be measured by load cells

It can fill bottles with 1 liter capacity to 4.5 liters.

Hard Facing Machine

This device is designed to harden the surface of tubes and shafts based on welding.

The object which is going to be hardened, will be located on the rotating rollers. The rollers rotates with adjusted speed which can be changed with a potentiometer on the control panel(Analog input).

The process will be started with activating the start button on the HMI monitor, then the welding inverter ,which is adjusted by considering the material and physical properties of the hardening object, will be started.

By starting the machine the rollers will rotate and the welding machine weld the surface, after each turn the nozzle will move forward. The amount of moving can also be adjusted through the HMI.

All these values must be matched to the material of the object.

After this process the surface tolerate against scratching with heavy things will be increased.

This device is designed to harden the surface of tubes and shafts based on welding.

The object which is going to be hardened, will be located on the rotating rollers. The rollers rotates with adjusted speed which can be changed with a potentiometer on the control panel(Analog input).

The process will be started with activating the start button on the HMI monitor, then the welding inverter ,which is adjusted by considering the material and physical properties of the hardening object, will be started.

By starting the machine the rollers will rotate and the welding machine weld the surface, after each turn the nozzle will move forward. The amount of moving can also be adjusted through the HMI.

All these values must be matched to the material of the object.

After this process the surface tolerate against scratching with heavy things will be increased.

SARAY-3

SARAY sterilization systems are autoclaved based sterilization systems which designed in order to sterile both waste and hospital equipment.

SARAY-3 can sterile the hospital equipment in less than an hour with steam power. It is a fully functional steam sterilizer for medical devices. This device uses autoclave to sterilize anything in high temperature and high pressure.

Programming this device is on the Siemens S7 series PLC.

It has a 400 liters reservoir made by stainless steel, with 2 automatic doors.

SARAY sterilization systems are autoclaved based sterilization systems which designed in order to sterile both waste and hospital equipment.

SARAY-3 can sterile the hospital equipment in less than an hour with steam power. It is a fully functional steam sterilizer for medical devices. This device uses autoclave to sterilize anything in high temperature and high pressure.

Programming this device is on the Siemens S7 series PLC.

It has a 400 liters reservoir made by stainless steel, with 2 automatic doors.

Plasma Sterilizer PS-140 Ver.0 (click for more information)

A Plasma Sterilizer is a low-temperature sterilizer intended to be used in clinics and hospitals to sterilize the medical instruments. This device uses Hydrogen Peroxide as a disinfectant and applies HV / LF plasma into its main chamber that is a high vacuum chamber to complete the sterilizing process.

This project was started in 2013 and we studied about this device in about 3 years and made a prototype of the sterilizer in 2015 in Kousha Metal Industries company.

A Plasma Sterilizer is a low-temperature sterilizer intended to be used in clinics and hospitals to sterilize the medical instruments. This device uses Hydrogen Peroxide as a disinfectant and applies HV / LF plasma into its main chamber that is a high vacuum chamber to complete the sterilizing process.

This project was started in 2013 and we studied about this device in about 3 years and made a prototype of the sterilizer in 2015 in Kousha Metal Industries company.

Plasma Sterilizer PS-140 Ver.1 (click for more information)

After testing the prototype, we tried to build a fully automatic and functional plasma sterilizer, which could be used in a hospital without our observation. We build the rectangular vacuum chamber in our next try.

It has an automatic door that could be controlled by a servo motor that we had learned to work with. The result of all the tests of the device like penetration test, biological indicators, chemical indicators was very good.

After testing the prototype, we tried to build a fully automatic and functional plasma sterilizer, which could be used in a hospital without our observation. We build the rectangular vacuum chamber in our next try.

It has an automatic door that could be controlled by a servo motor that we had learned to work with. The result of all the tests of the device like penetration test, biological indicators, chemical indicators was very good.

Plasma Sterilizer PS-140 Ver.2 (click for more information)

We tried to build the second version of our plasma sterilizer with two doors, all of the parts had been designed again. The vaporizer part in this version is controlled by the varying current of the thermoelectric coolers.

We improved our designs in this version.

We tried to build the second version of our plasma sterilizer with two doors, all of the parts had been designed again. The vaporizer part in this version is controlled by the varying current of the thermoelectric coolers.

We improved our designs in this version.

Plasma Sterilizer PS-140 Ver.3 (click for more information)

This is the last version of our sterilizer. It is smaller in dimensions and faster than our late versions. It is more efficient and with much lower noise. It needs just a 220V/1ph electrical supply.

This is the last version of our sterilizer. It is smaller in dimensions and faster than our late versions. It is more efficient and with much lower noise. It needs just a 220V/1ph electrical supply.

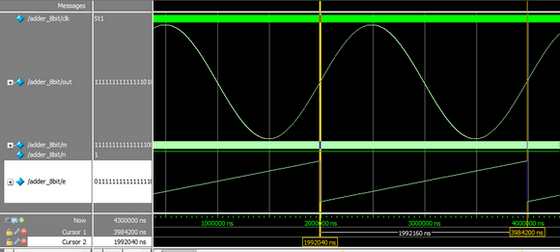

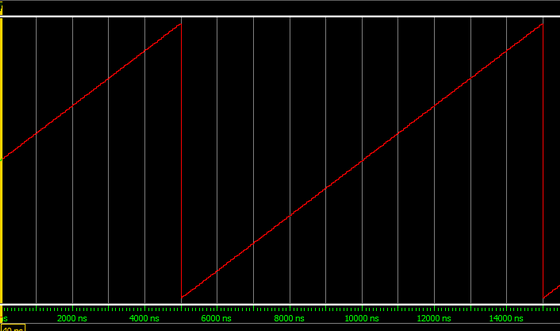

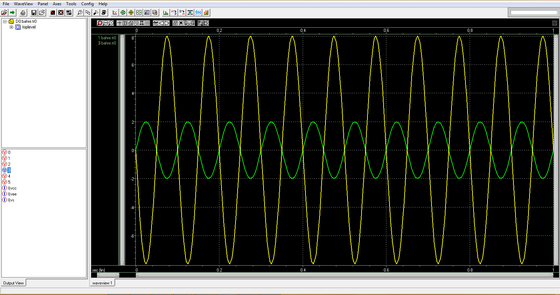

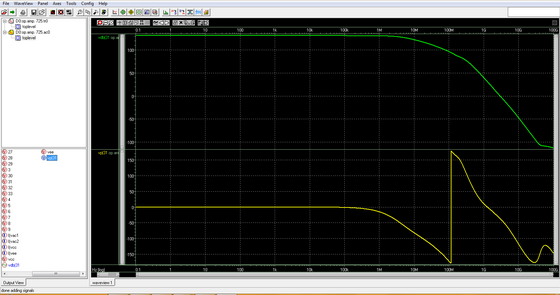

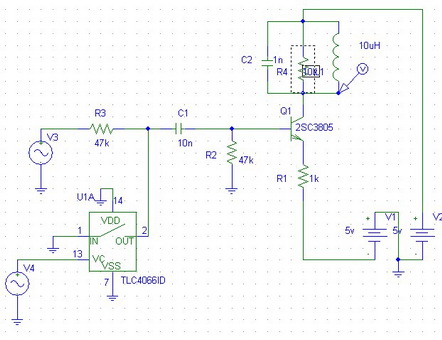

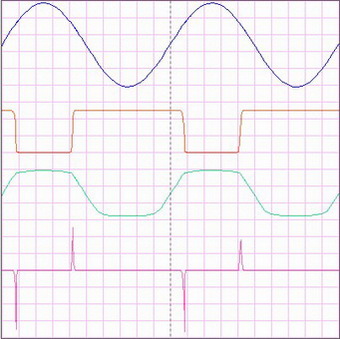

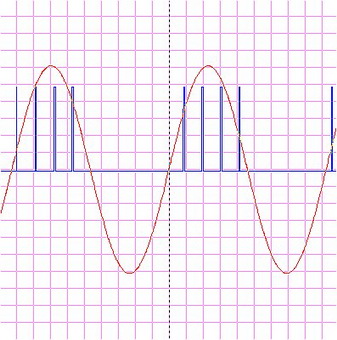

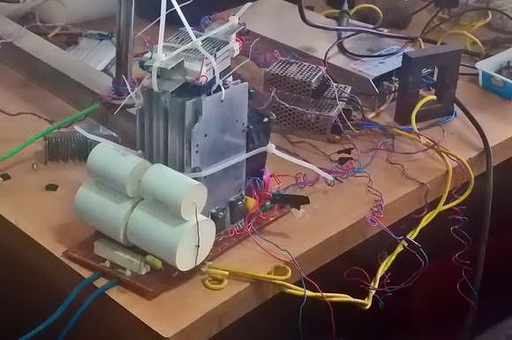

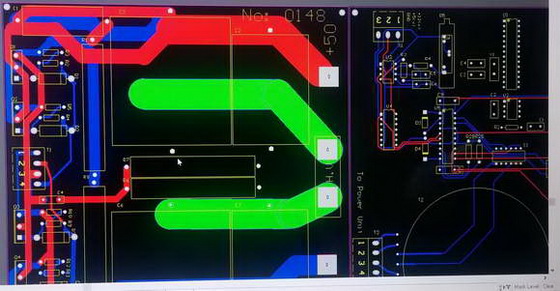

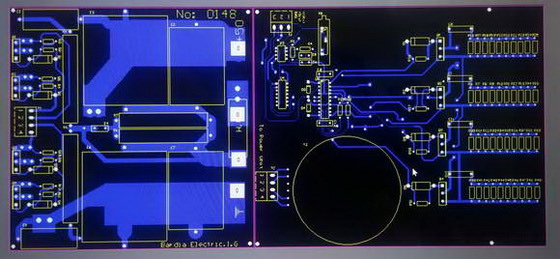

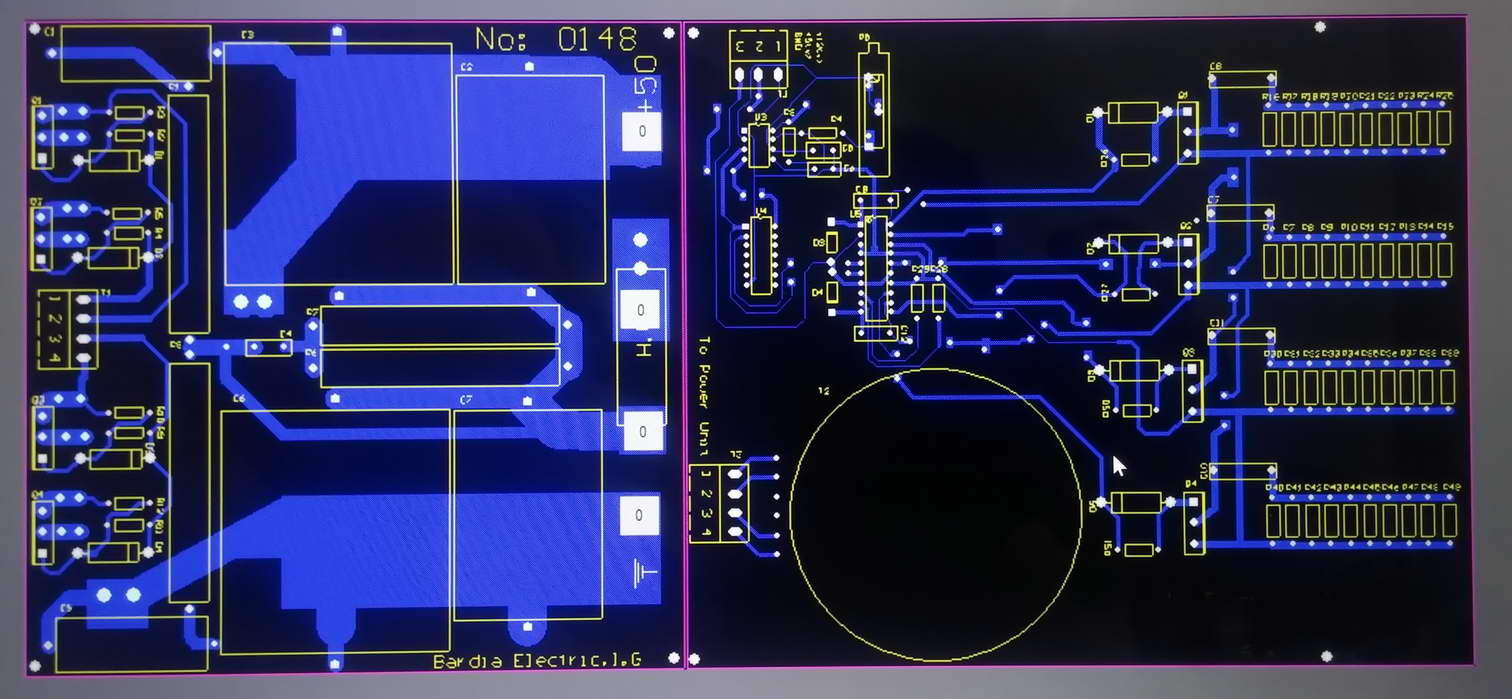

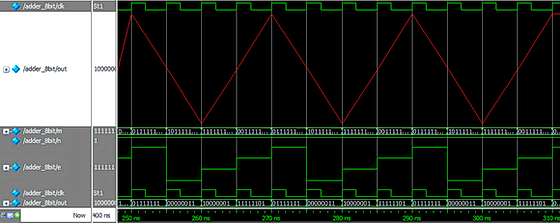

An FPGA based DDS System

As an Electronics Engineer, in 2012, I had the opportunity to work with FPGA boards, like Cyclone 2 DE.

The project defined in order to generate high precision wave with FPGA.

I programmed the FPGA using Quartus design software.

After designing, I tried to simulate the output via Model Sim simulation environment software.

The designing was implemented on Cyclone FPGA.

As an Electronics Engineer, in 2012, I had the opportunity to work with FPGA boards, like Cyclone 2 DE.

The project defined in order to generate high precision wave with FPGA.

I programmed the FPGA using Quartus design software.

After designing, I tried to simulate the output via Model Sim simulation environment software.

The designing was implemented on Cyclone FPGA.

Bachelor of Science

in Electrical Engineering

University Of Guilan (2008-2012)

in Electrical Engineering

University Of Guilan (2008-2012)

I studied electrical engineering at the University of Guilan in Rasht, a beautiful city in the north of Iran, and I graduated in 2012.

After graduation, I started my first job as an automation engineer in automation department at Kousha Metal Industries co, which has designed and manufactured different types of products in different field as hospital equipment, oil & gas and petrochemical industries, and food industries.

It was a great experience for me and in that period I was working on different types of machines with various process implementation that every one had its own special installation. Furthermore, I worked and got familiar with different brands of devices such as Siemens, Delta, Fatek that are being used in the implementation of an automation system.

It was a great experience for me and in that period I was working on different types of machines with various process implementation that every one had its own special installation. Furthermore, I worked and got familiar with different brands of devices such as Siemens, Delta, Fatek that are being used in the implementation of an automation system.

After 2 years of working in the automation department, I went to the R&D department and an important step in my career started.

In this period with my friend and my colleague, Hossein Pouresmaeeli, were working on various project that we succeeded in some of them and unfortunately in some of them for various reasons such as changing in priorities of the company we could not finish the project, but it was a valuable experience for us because we had to learn different kinds of skills for every project while in some of these skills we had no previous experience.

In this period with my friend and my colleague, Hossein Pouresmaeeli, were working on various project that we succeeded in some of them and unfortunately in some of them for various reasons such as changing in priorities of the company we could not finish the project, but it was a valuable experience for us because we had to learn different kinds of skills for every project while in some of these skills we had no previous experience.

After producing the prototype and first version of Plasma Sterilizer the Company has decided to manufacture it with a new brand as Atie Medical Industries, so we moved to this company as a project manager of Plasma Sterilizer project

One of the useful skills that we learned in the R&D department was modeling and designing parts by Autodesk Inventor Software that was really a necessary skill in any kinds of designing. Here are some examples of my work.

Programming:

Python

+5000 Lines

+5000 Lines

MATLAB

+3500 Lines

+3500 Lines

JAVA

+2000 Lines

+2000 Lines

Android

+1000 Lines

+1000 Lines

iOS

+5000 Lines

+5000 Lines

IC Programming

+3000 Lines

+3000 Lines

Ladder Logic Programming

+4000 Networks

+4000 Networks

C++

+2500 Lines

+2500 Lines

Designing:

After getting different experiences in the manufacturing process, and designing control systems, I would like to pursue my career in an advanced level of Mechatronics, Robotics and Internet of Things (IoT) especially I would like to use AI and Machine Learning for These Systems.